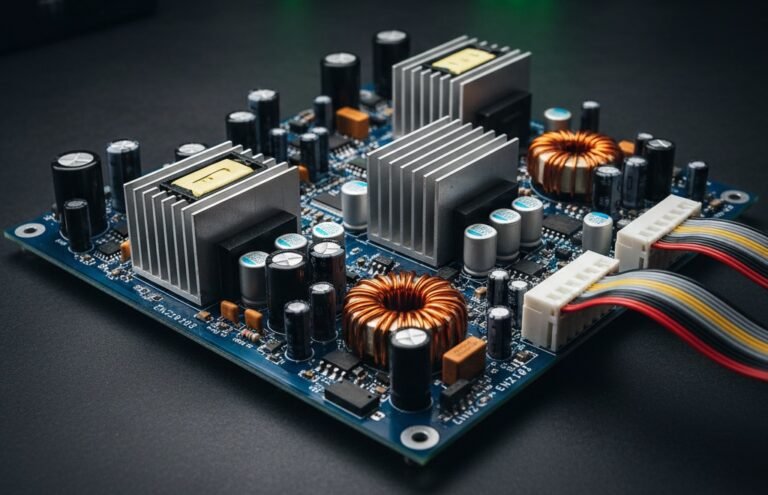

Solid-State Power Converters

We are advancing solid-state power converter technologies using wide-bandgap devices (SiC/GaN) for high efficiency, compact size, and intelligent control. Core areas include:

High-frequency switching for improved power density

Bidirectional converters for grid, storage, and EV systems

Intelligent digital control and real-time monitoring

Modular and scalable architectures

Enhanced protection and thermal management

These platforms enable next-generation solutions for smart grids, renewables, and electric mobility.

Advanced Power Converter Technologies

Our R&D spans a complete suite of high-performance power conversion systems:

DC–DC converters for regulated and isolated power delivery

AC–DC converters with stable, low-noise outputs

SMPS for compact, high-efficiency applications

Solar power converters optimized for maximum panel utilization

EV power modules supporting fast charging and high-power operation

Programmable laboratory power supplies built for precision R&D environments

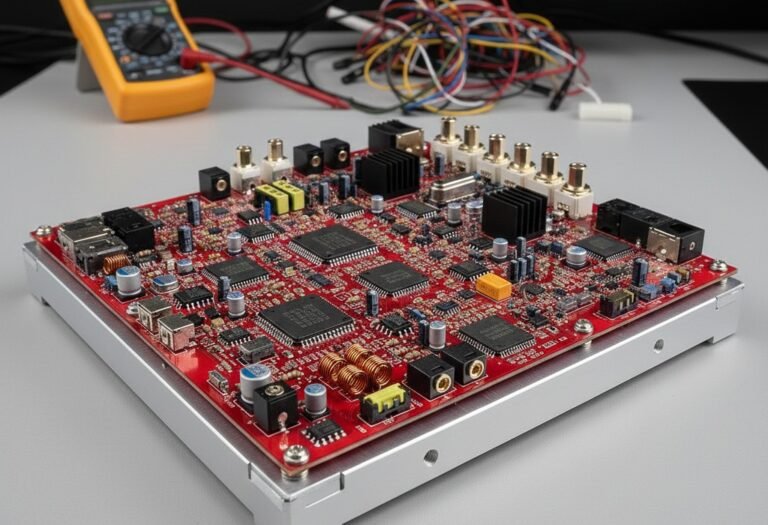

Customized Electronic Circuits

We specialize in designing and developing customized electronic circuits tailored for precision, performance, and application-specific requirements. Our R&D work focuses on three core areas:

Analog Circuit Design

Precision signal conditioning

Low-noise front-end circuits

Sensor interface modules

Filtering, modulation, and measurement circuits

High-stability reference and control circuits

Amplification Systems

Low-noise amplifiers (LNA)

High-gain instrumentation amplifiers

Power amplifiers for industrial and research applications

Wideband and high-frequency amplifier stages

Linear and switching amplifier architectures

Power Conversion Circuits

High-efficiency DC–DC and AC–DC stages

SMPS-based compact designs

Gate drivers and control circuits for power devices

Protection, monitoring, and feedback control circuitry

Custom power modules for EV, renewable, and industrial systems

Each solution is built to ensure reliability, thermal stability, noise immunity, and seamless integration into larger systems.

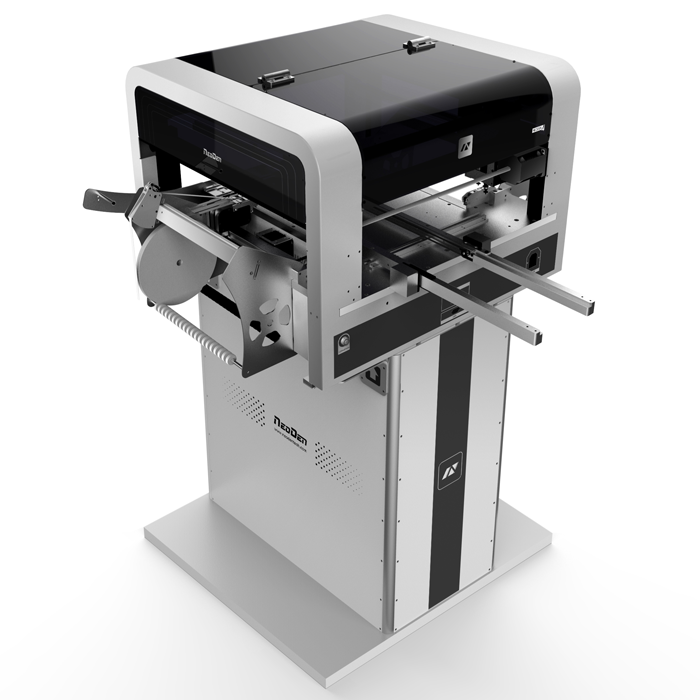

Advanced Automatic SMT Desktop Pick and Place machine

We maintain advanced R&D facilities in collaboration with KUMAR AUDIOS Company, enabling high-precision electronics development and prototyping. Our shared infrastructure includes the NeoDen N4+ Automatic SMT Desktop Pick-and-Place machine, equipped with a highly intelligent flying vision system—the first of its kind in its class. This fully automatic SMT platform enhances productivity through rapid, accurate component placement, achieving up to 5,000 CPH with the vision system and up to 10,000 CPH in the standard configuration. It supports a wide range of components from 0201 to TQFP240, including QFN, BGA, and SOT-23 packages, with flexible feeder options such as 48 tape reel feeders, vibrating tube feeders, and tray support. The system accommodates PCBs up to 310 × 1500 mm and integrates seamlessly with design tools like Altium, Eagle, and KiCad. Through this collaboration, we offer industry-grade electronic assembly capabilities for research, innovation, and product development.

Advanced Semi-Automatic SMT Reflow Oven

We have the NeoDen IN6 reflow oven as part of our R&D manufacturing setup, offering a compact and efficient solution for high-quality soldering. With precise temperature control, multiple heating zones, and a built-in smoke filtration system, it delivers consistent and reliable soldering performance for various PCB assemblies. Its user-friendly interface and versatile operation make it ideal for both rapid prototyping and medium-scale production, supporting clean, efficient, and modern electronic manufacturing workflows within our facility.

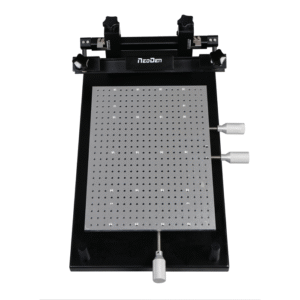

Manual SMT Solder Printer

We have a Manual Solder Printer for framed stencils, providing a simple and reliable method for applying solder paste to PCBs with consistent accuracy. This setup ensures clean, uniform deposition for both prototype and small-batch manufacturing, making the PCB assembly process efficient and repeatable in our R&D environment.

We have a digital-controlled ultrasonic cleaner for PCB cleaning, offering 500W of powerful ultrasonic action with multiple functions to ensure thorough and efficient removal of flux residues, dust, and contaminants. Its precise control system and high-frequency cleaning capability provide deep, uniform cleaning for delicate electronic assemblies, supporting reliable post-solder and maintenance workflows in our R&D facility.

Digitally Controlled Lead Solder Pots

We have multiple-size, digitally controlled lead solder pots suitable for working on single PCBs from small to large, supporting board sizes up to 13x30 cm. These units provide stable temperature control and smooth solder flow, ensuring reliable tinning, desoldering, and manual assembly across a wide range of PCB sizes in our R&D workflow

Advanced Metering and Measurement Tools

We have multiple measurement instruments, including dedicated meters for voltage, current, capacitance, inductance, and power, along with precision multimeters and customized meters capable of measuring a wide range of electrical and electronic parameters. Our facility is also equipped with oscilloscopes and signal generators for advanced waveform analysis and signal characterization. Together, these tools enable accurate testing, validation, troubleshooting, and detailed characterization across all our R&D activities.

Precision SMD Assembly and Rework Tools

We have SMD rework stations and multiple SMD soldering stations, enabling precise component handling, removal, and soldering for a wide range of surface-mount devices. These tools support fine-pitch repairs, prototype assembly, and detailed rework operations across our R&D projects.